Inventory tracking is a very important and powerful tool for many industries. Knowing what inventory is on hand and being able to track product trends allows the business owner to better forecast what they need to produce and when. This allows production resources to be focused where they are needed most, eliminates delays, and makes for a more consistent product flow which can lead to higher profits.

So what is inventory tracking? It is a tracking system that utilizes software which enables companies to manage and track raw materials and products as they go through different stages of the production process. This software utilizes different tools and methods such as barcode scanners, RFID tags, manually inserting data, and others to collect the necessary data. The data that is collected allows production managers to create reports and view trends on the materials being used and products being made. That information promotes more informed decisions about when and how much of a material to order. It can also help with production scheduling, as well as understanding what products are selling the best.

Inventory tracking utilizes a database to store a wide variety of specific details about raw materials, products being made, and who receives the finished products. Some examples of details that can be useful in the raw materials database include: a complete list of raw materials, who the supplier is, the date and amounts of materials were received, the price paid for each, and even an expiration date if the material is a perishable item.

With this information, production managers can also create a products database. Some useful information that might be stored in this database are: complete product lists, when and where each was produced, what materials were used in making the product, how long a product has been in the warehouse, as well as when and where finished products are shipped. You can also run reports and view details about what raw materials were used to create batches of products. This allows production managers to apply recalls to a more specific range of products should it become necessary. This can significantly reduce the negative impact a recall has on the company.

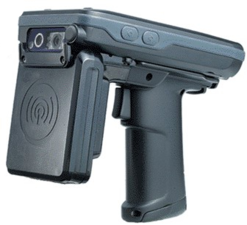

This may sound like a lot of information to collect and keep track of. But as mentioned previously, there are many different ways to obtain this information and get it into a database. I will discuss two of the best methods: the barcode scanner and RFID (Radio Frequency Identification).

This may sound like a lot of information to collect and keep track of. But as mentioned previously, there are many different ways to obtain this information and get it into a database. I will discuss two of the best methods: the barcode scanner and RFID (Radio Frequency Identification).

Barcode scanners allow you to simply place a barcode on items as they are received and scan them into inventory. If this item has been received before, scanning each new shipment will add another entry into the database with the current date and time, linking it with the specific material has been received, you will need to enter basic information about the material to the database. Barcodes can also be used during production. Raw materials that become part of a finished product are simply scanned as they are used, and the database is automatically updated.

Barcode scanners allow you to simply place a barcode on items as they are received and scan them into inventory. If this item has been received before, scanning each new shipment will add another entry into the database with the current date and time, linking it with the specific material has been received, you will need to enter basic information about the material to the database. Barcodes can also be used during production. Raw materials that become part of a finished product are simply scanned as they are used, and the database is automatically updated.